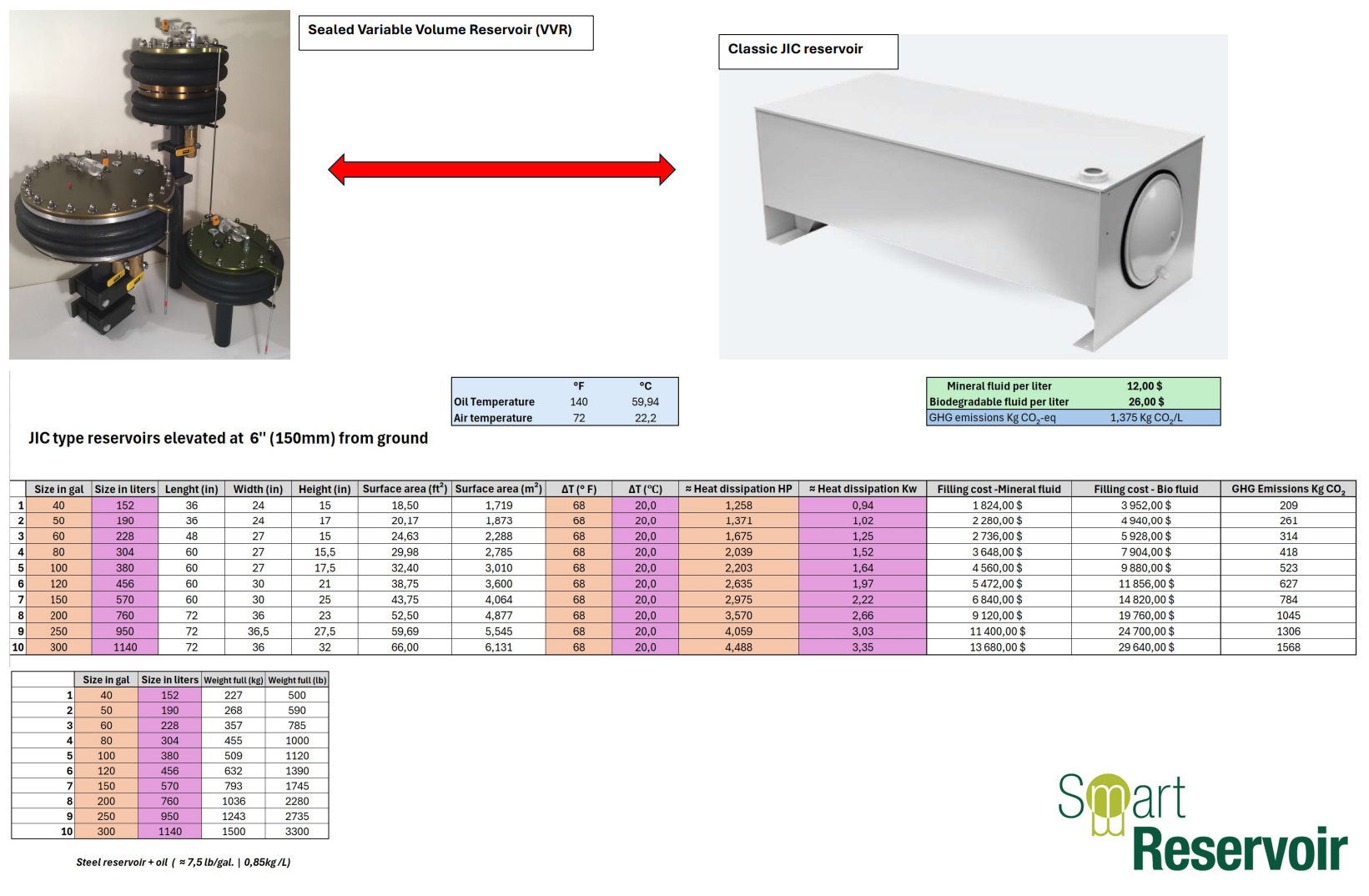

Fluid cooling

Many systems are currently designed with oversized reservoirs as they are believed to act as oil cooler. Conventional reservoirs do cool oil but minimally. Today's high performance coolers can perform all the cooling requirements by themselves while being light and compact. A properly sized coolers will keep the system temperature within the desired range whatever the environment. Traditional reservoir requires appropriate differential temperature ratio between oil and ambient air to perform in that matter and even so, their cooling capacity is modest at best. The following example shows the relative limited cooling capacity of conventional reservoirs vs. coolers.

Thermal capacity

- Typically, 25-30% of a system power is required in cooling capacity

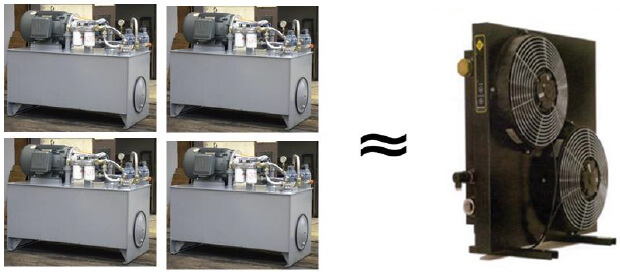

- A 75 gal (284 L) conventional reservoir will only provide 3-4 hp / 2-3 Kw of cooling capacity in typical conditions. Four to five reservoirs would be required to match the cooling capacity of an air/oil type cooler like shown below. Further, the corresponding weight shall not be neglected

- 4 x 75 gal = Total weight ≈ 3750 lbs / 1700 kg

(Download PDF )

Too often conventional reservoirs are used to cool the fluid.

It shouldn't be their task!

- Any reservoir has limited cooling capacity and many inconveniences

- The optimum solution is the heat exchanger

- Most systems already include a heat exchanger so there should be very little to no extra cost to incorporate a VVR

- ONLY the heat exchanger should provide fluid cooling

The typical 2-3 minutes dwell time found on classic reservoirs to eliminate air bubbles is no longer a necessity when using the VVR since the system is sealed and airless. However a specific procedure must be followed to bleed the system (see Fill procedure).